The double intersection warren truss bridge across Flatt’s Inlet – a small channel which joins Harrington Sound with the Atlantic Ocean – is one of numerous crossings which have been built or are planned to restore the historic Bermuda Railway Trail and enhance connectivity between public green spaces on the highly urbanised island. The coastal route once had 33 bridges and trestles along its 35km length and was the primary mode of transportation for passengers and freight on the island from 1931 to 1948.

Pultruded FRP was selected as the main structural material due to it being lightweight and having a lower carbon footprint than steel or concrete

The original crossing at Flatt’s Inlet was a 12.2m-high trestle with steep grades on either side which carried trains across the waterway. Piers were built on concrete columns founded in the water, and two groups of four columns remained prior to the project being launched in 2017 by local charity, Friends of Bermuda Railway Trail.

The organisation raised the necessary capital from local private investors and commissioned Creative Composites Group (CCG) to source an FRP pedestrian bridge that could span the inlet from its ET Techtonics line.

“FRP offered corrosion resistance and minimal maintenance,” says Tucker Murphy, one of three founders of the charity along with his sister Laura and father Lawrence. “Maintenance is a huge issue for us due to the harsh, salty environment. We also have a limited workforce because we’re a small island. FRP met our goals for a reduced environmental footprint and the truss design fit the historical narrative we wanted to preserve.”

A study into the project’s feasibility was then undertaken by Eric Johnasen, president of Fibreglass Trusses, who had designed the ET Techtonics FRP building blocks using off-the-shelf components before selling the firm to Creative Pultrusions in 2016. Once the project was deemed feasible, a preliminary design and computer model simulation were generated to show the bridge would perform to help provide a cost estimate.

With a lot of moving parts in play, Laura Murphy, who had worked for the Department of Planning, spearheaded getting plans approved for the Flatt’s Inlet. This involved presenting the concept to the ministers of environment and public works as well as the then Premier, the Hon. Michael Dunkley, JP, MP. “We got a good response and were given the go ahead to submit the concept to the rest of the cabinet,” she says. After gaining a political consensus, Laura tackled consultations with seven different government departments and sections, as well as special stakeholder groups.

“We had to meet with the tour boat operators to determine how high the bridge needed to be,” she says. “We also had to consider special circumstances, such as the fact that the bridge site was in a cave protection zone. An extensive cave system is located near the building site. You can’t actually go in and explore these caves, but it meant we couldn’t excavate very deep without first drilling additional exploratory boreholes. That’s one of the reasons we chose to install the FRP bridges on the existing railway supports, where possible.”

FRP supported the requirements of the Marine Resources Board as well. Spans were lightweight enough to rest on the existing supports in the inlet, reducing the need for extensive construction in a sensitive marine environment, which is home to coral and sea life, from spotted eagle rays to the occasional hammerhead shark.

Its design flexibility also suited the narrow work spaces on the Railway Trail, as bridges could be assembled off-site, and bridge lengths could be easily adjusted to avoid siting new foundations too close to the three utility lines running under the surface of the trail. “We held a public meeting and then submitted our application to the Department of Planning along with a marine traffic study and conservation management plan,” Laura says. “The cost for labour and services is very high in Bermuda, so anything that we could do ourselves, we did, in order to keep project costs low.”

Once plans were approved, CCG was tasked with designing and fabricating the longest clear span pultruded FRP truss bridge in the world. Plans specified a clear span bridge 46.3m long and 2.4m wide. Prior to the Flatts Inlet installation, ET Techtonics had only produced spans up to 35m long with a double truss system above and below the deck.

“We had some challenges,” says Dustin Troutman, director of marketing and product development for CCG. “It took us a couple of months to design the bridge to international building codes, but we constructed it stateside in about two weeks.”

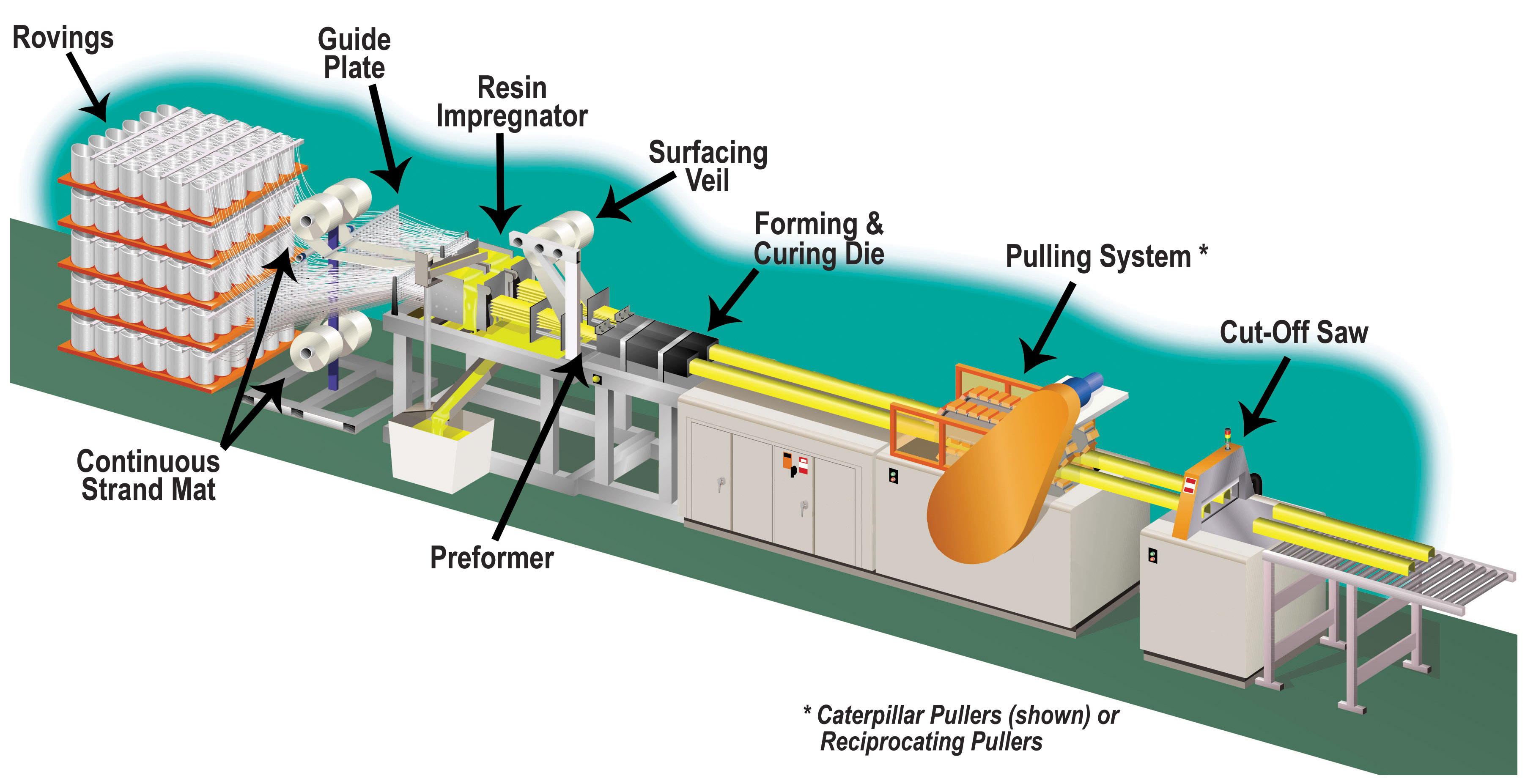

A continuous manufacturing process, pultrusion creates high-strength, lightweight FRP structural profiles such as angles, C-channels and I-beams. Fiberglass reinforcements in the form of roving and mats are saturated with resin and channelled into a heated die. The profile exits the die in the form of the desired cross section or shape. Pultruded profiles have a higher tensile strength than conventional steel but are approximately 80% lighter.

A schematic of the pultrusion process

A schematic of the pultrusion process

Pultruded profiles provide a lower carbon footprint than steel and aluminium, and because the material is inert, chemicals are not leached into the environment. To build the truss bridge, pultruded pieces were cut, drilled and bolted together.

“Testing took two days,” says Troutman. “One day for a lift test with a crane and one day for a load bearing test. Since the job site was in the middle of the water, building the bridge in situ was not an option. We had to make sure the crane [and barge] at the Bermuda job site could effectively pick up the entire bridge span based on the specified rigging and pick plan.”

“The load test was the largest pedestrian bridge test ever performed,” says Johansen. “You don’t typically build a structure to full scale and then load test it. Creative Pultrusions did an excellent job orchestrating the logistics.” Wooden holding tanks were filled with water and uniformly placed along the bridge deck surface to simulate the bridge filled to capacity with people. Approximately one hundred thousand pounds of water simulated 500 pedestrians on the bridge. Test results were close to a pedestrian load of 366.2kg/m2, exceeding design requirements specifying 317.4kg/m2.

Once safety and performance parameters were verified, the bridge was disassembled, packaged, kitted into three 12.2m storage containers and shipped to Bermuda. Friends of Bermuda Railway Trail assembled a small crew of dedicated volunteers. Families, retirees, trail walkers, local engineers/architects, and even one sailor stranded in Bermuda by the pandemic, met the container, unpacked it and re-assembled the bridge in a manner “as straight forward as that of an Erector Set”.

“It demonstrates how easy it can be to assemble composites due to their lightweight nature,” says Johansen. “Ease of assembly can also translate to huge cost savings.”

The 46.3m-long bridge was assembled in the autumn of 2020 at the island’s historic dockyard. On 13 December 2020, [following pre-approved rigging instructions], the span was loaded onto a barge with a large crane and ferried to the installation site on 14 December 2020, where it was lifted with the barge crane onto the remediated concrete supports.

The span was lifted into place by a barge crane on 14 December 2020

The span was lifted into place by a barge crane on 14 December 2020

The clear span is the first of several bridges that will be installed to reconnect the trail across Flatts Inlet, and in June Friends of Bermuda Railway Trail received its building permit to dig foundations and construct the piles for the next bridge. The organisation expects to assemble and install the next FRP spans this summer.

Experience delivering other FRP footbridges to the island prior to the Flatt’s Inlet project helped inform and guide the charity’s decisions. In 2013, the group got their feet wet with their first project: Bailey’s Bay. It entailed a total of 13 bridges including a series of spans that crossed Bailey’s Bay and reconnected two trail sections.

“We wanted a durable, lightweight bridge that could withstand a harsh environment,” says Tucker Murphy. “We found the ET Techtonics pultruded FRP bridge and walkway products online. My dad travelled to the States to take a look at the technology and thought it would work well for our application in Bermuda.”

Just two weeks after the majority of the bridges were installed at Bailey’s Bay, the island was hit with back-to-back hurricanes. Wind speeds were clocked at up to 231km/h. “The island sustained a lot of damage, but the bridges came through completely intact,” says Eric Johansen. “With projects like this one, it’s all about testing [whether in the lab, or in the field], but you can’t simulate something like this. Those tropical cyclones proved that the product worked under hurricane conditions.” The island and the Bailey’s Bay FRP bridges have since endured four more hurricanes.